QUALITY

One Heart, One Stitch.

Our Stitches Connect the Future.

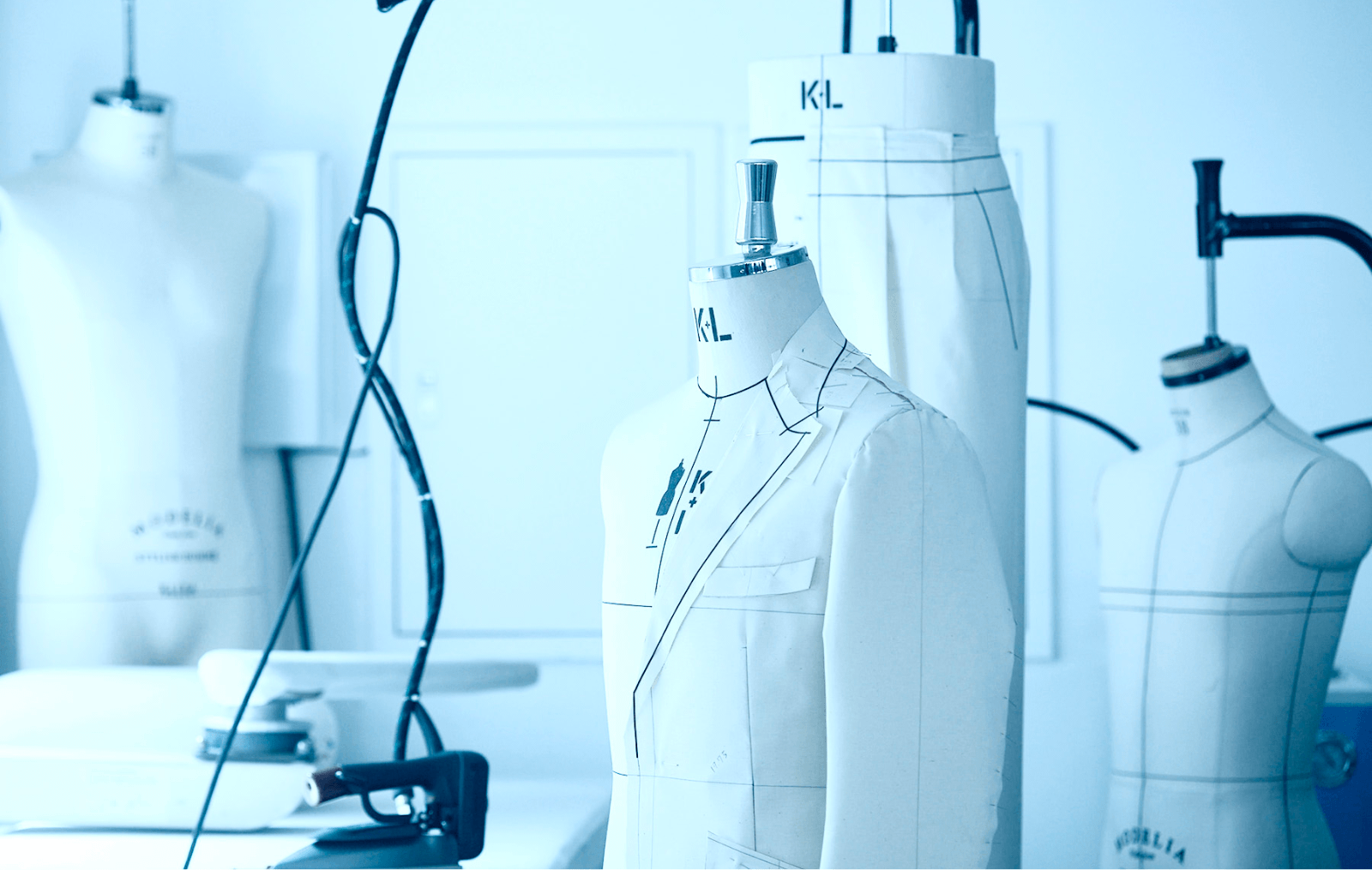

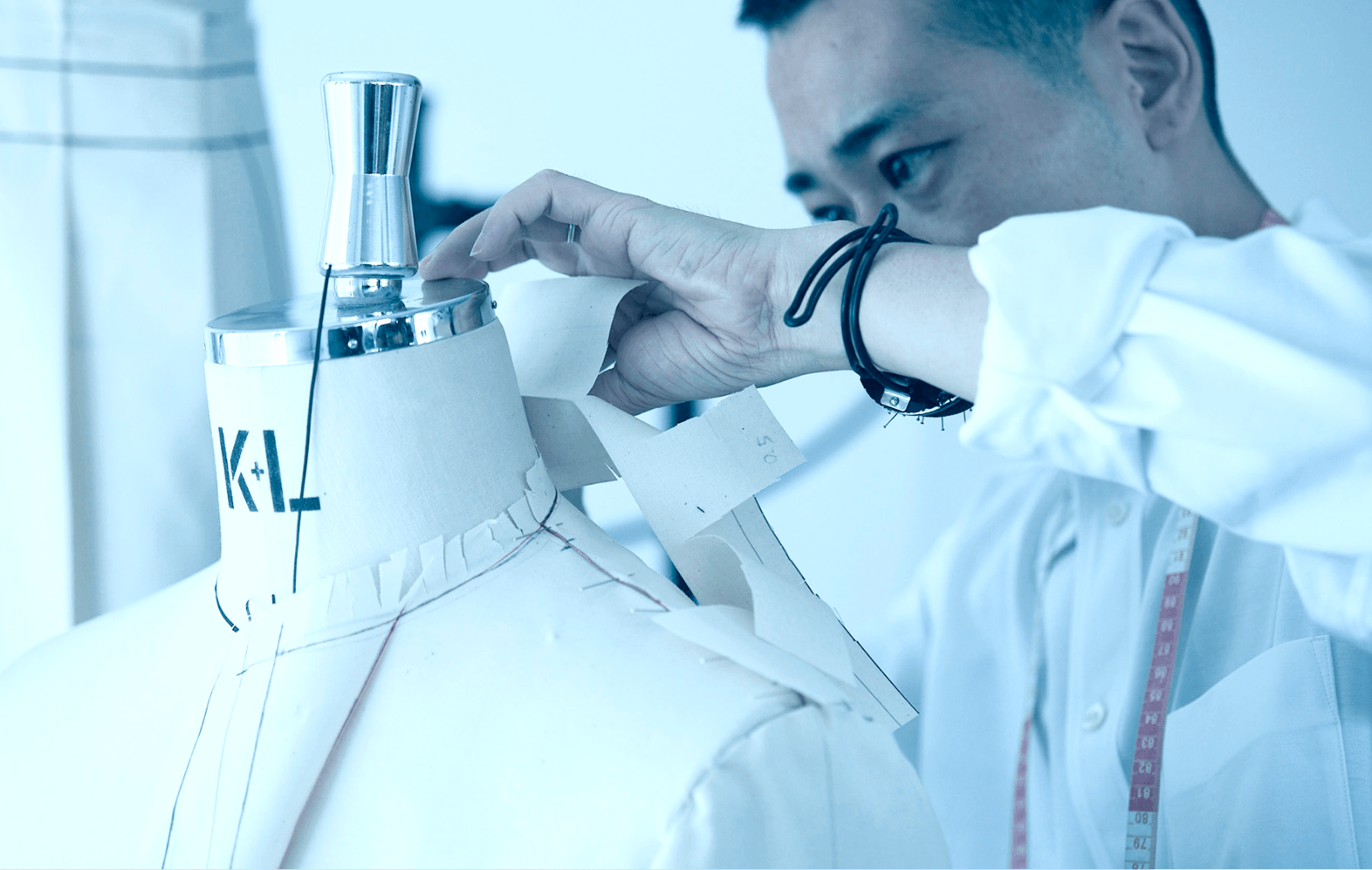

Sewing is not a skill acquired overnight. At MARUCHO factories, veteran artisans pass their skills on to younger workers, who inherit mindful sewing techniques.

In addition to refining traditional skills, we are proactively investing in plant and equipment to advance our SMART FACTORY initiative, aiming to increase productivity without sacrificing quality.

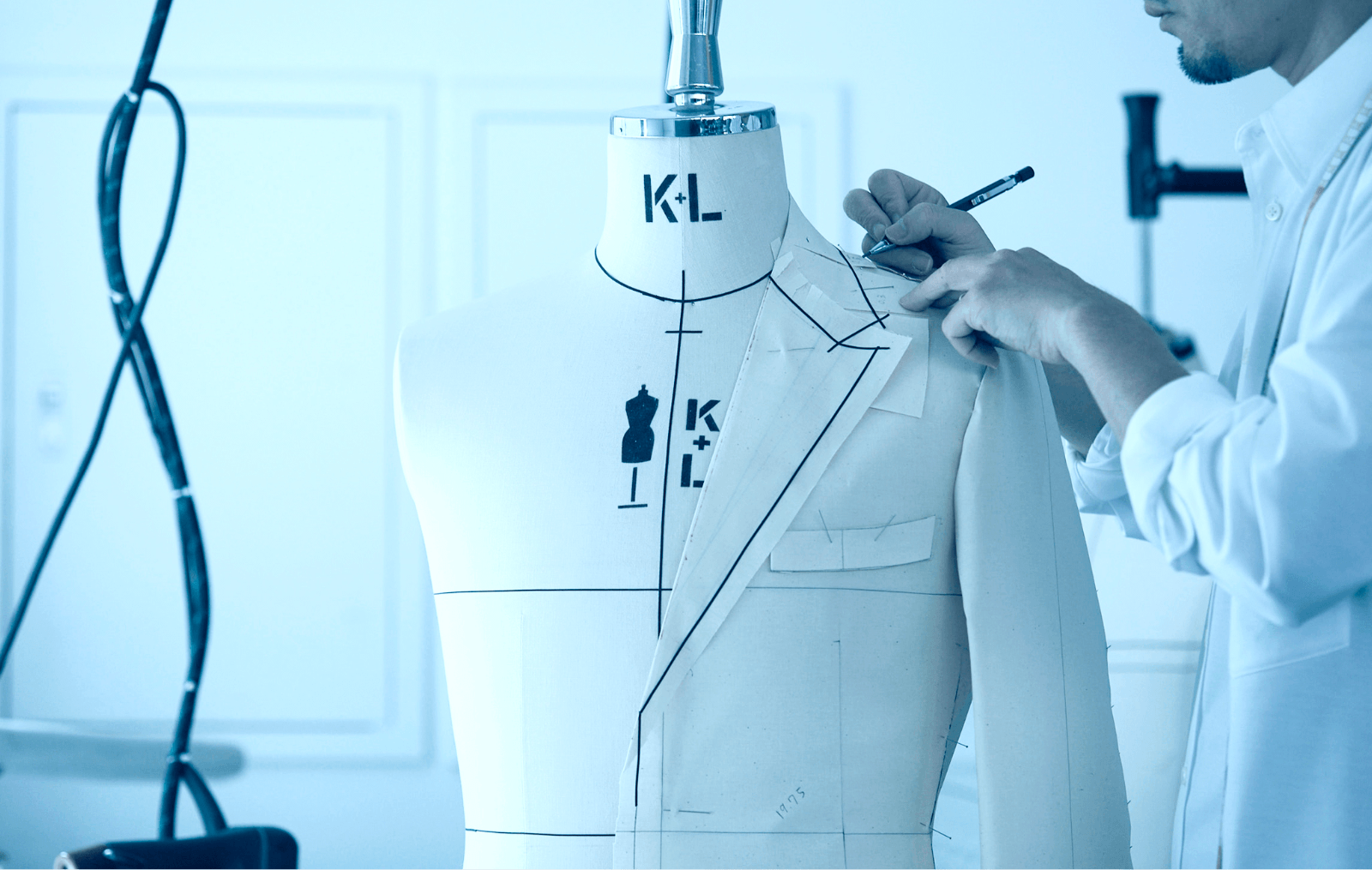

We employ our own pattern makers, and are focusing on enhancing pattern-making technology. Various seminars are organized to encourage mastery of tailoring skills. Our workers are eager to acquire new skills to ensure customer satisfaction, including hand-sewing and forming-press skills, armhole fitting techniques and other specialized processes.